Shipping ROI is more than a metric, it is a measure of how effectively shipping becomes a strategic advantage rather than a cost burden. In a world where supply-chain volatility, customer expectations, and cost pressures are mounting, understanding ROI in shipping gives logistics leaders the clarity and confidence to invest in smarter, data-driven solutions. Shipping ROI represents the return gained, in cost savings, speed, reliability, and visibility, when shipping operations are optimized through technology and smart processes.

When shipping is managed manually or through fragmented carriers and legacy workflows, inefficiencies hide behind complexity: unpredictable costs, lack of visibility, manual errors, and delays. These all erode profit margins and hinder growth. On the other hand, a well-implemented smart shipping strategy, anchored in analytics, automation, real-time tracking, and intelligent decision-making, can transform shipping into a lever for cost reduction, operational efficiency, and competitive advantage.

In this post, we explore how shipping ROI is realized in practice, what makes it possible, what challenges to watch out for, and how a modern logistics platform (like the one offered by eShipz) can help businesses maximize shipping ROI without directly “pitching” but through value-driven capability.

Improving Logistics ROI Through Smarter Shipping Practices

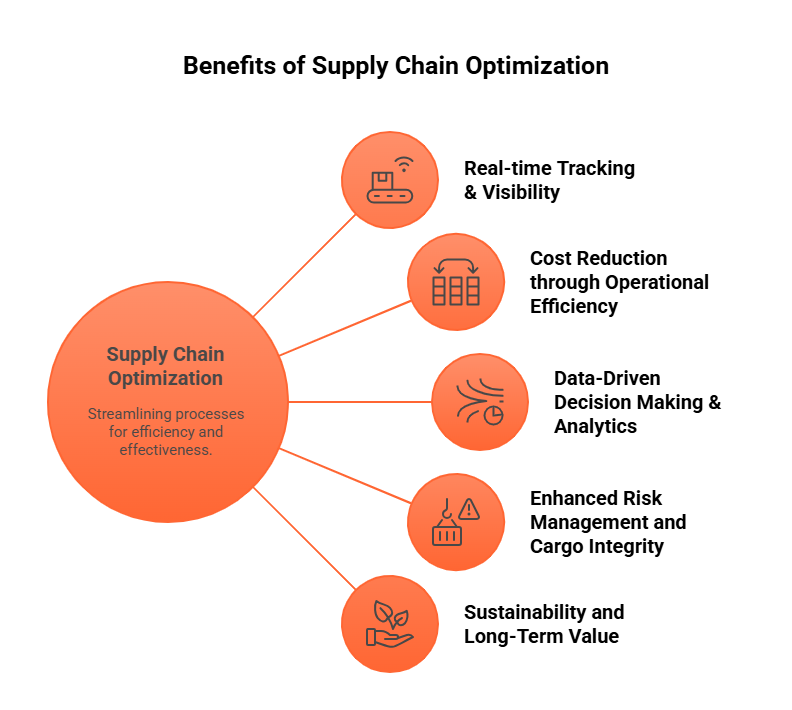

Achieving strong shipping ROI hinges on a combination of technology adoption, data-driven decisions, and streamlined operations. Here are how modern shipping solutions deliver ROI and improve supply-chain performance:

1. Real-time Tracking & Visibility

One of the biggest pain points in traditional shipping is the lack of visibility. Without clear, up-to-date information about where a shipment is, its status, or its condition, supply-chain managers are always playing catch-up, which leads to delays, lost cargo, inventory mismanagement, and unpredictable costs.

Smart shipping solutions now harness IoT, telematics, and container-tracking technologies to provide real-time visibility into cargo location, condition, and transit status.

This visibility enables better planning, faster response to delays or disruptions, and more accurate logistics coordination across warehouses, ports, and carriers. That alone drastically reduces the risk of lost or delayed shipments and supports better customer service.

2. Cost Reduction through Operational Efficiency

When shipping operations are automated and optimized, companies avoid many hidden costs associated with manual workflows, redundant paperwork, manual inspections, inefficient routing, and delayed documentation.

For example, in container shipping, smart containers can cut down manual inspections (particularly for reefer or temperature-sensitive cargo), leading to labour savings, lower energy use, and less cargo spoilage.

Moreover, better inventory management and optimized container use (fewer idle containers, fewer empty repositioning trips) reduce storage and logistics overhead.

Smart systems also support predictive maintenance, avoiding unplanned downtime or costly breakdowns by catching problems before they happen.

All this adds up to lower shipping costs, improved asset utilization, and ultimately a stronger return on shipping investments.

3. Data-Driven Decision Making & Analytics

With modern shipping and logistics platforms, companies gain access to powerful analytics: carrier performance, transit times, cost per shipment, rate comparisons, delivery success rates, and more. This data-driven logistics approach replaces guesswork with evidence-based management.

Such insights help supply-chain leaders choose the most cost-effective carriers, optimize shipping routes, schedule shipments to avoid delays or surcharges, and make strategic decisions on logistics procurement. The result: improved service levels, reduced wastage, and maximised shipping ROI.

4. Enhanced Risk Management and Cargo Integrity

Smart containers and IoT-enabled shipping monitor environmental conditions (temperature, humidity, shock), route deviations, unauthorised access, and other risks throughout the journey. This protects sensitive or perishable cargo and reduces losses due to damage, spoilage, or theft.

For perishable goods, pharmaceuticals, or high-value items, this improved safety and compliance assurance can save a company from costly claims, waste, or reputational damage, contributing directly to positive shipping ROI.

5. Sustainability and Long-Term Value

Efficient route planning, reduced idle times, fewer empty container repositioning trips, and intelligent logistics contribute to lower fuel consumption, reduced emissions, and more sustainable supply chain operations.

As consumers and regulators increasingly value sustainability, this environmental efficiency translates into long-term savings and improved brand value, adding to the broader ROI from smarter shipping.

Strategies to Improve Shipping ROI

While the benefits of smart shipping are significant, both shipping ROI and logistics ROI are not automatic. Supply-chain leaders must focus on specific strategies to overcome operational challenges and maximize returns across the logistics function.

1. Initial Investment and Technology Adoption

Transitioning from legacy workflows to modern, tech-enabled shipping systems (IoT devices, telematics, and integrated shipping platforms) requires upfront investment. These costs include sensor-enabled assets, software onboarding, connectivity, and team training. Viewing this as a long-term investment is essential. The improvements in operational efficiency, reduced manual work, and better logistics ROI compound over time, delivering measurable savings.

2. Data Overload and Integration Complexity

Every shipment now produces data on route, location, environmental conditions, delays, and exceptions. Without a strong analytics layer, this information can overwhelm teams. To unlock both shipping ROI and logistics ROI, companies need systems that integrate seamlessly with warehouse management, ERP, and order-management platforms. This ensures consolidated visibility and full automation across the supply chain.

3. Connectivity and Infrastructure Limitations

Smart tracking and real-time visibility depend heavily on stable communication networks. In remote or low-coverage regions, lack of connectivity can reduce tracking accuracy and delay critical alerts. This impacts decision-making, exception handling, and overall ROI. Addressing connectivity gaps is essential for consistent performance across logistics operations.

4. Balancing Cost vs Benefit and Measuring ROI

Improving shipping ROI requires clear metrics. These include cost per shipment, manual labour savings, spoilage reduction, faster delivery times, and improved container utilisation. But logistics ROI goes beyond cost—it includes customer satisfaction, service-level improvements, compliance gains, reduced claims, and sustainable practices. Companies must evaluate both financial and operational impacts to understand the true return from smarter shipping solutions.

5. Adoption and Change Management

Technology alone cannot optimize logistics ROI. Organisations must prepare teams for new workflows, carrier integrations, automation rules, and dashboards. Lack of team buy-in, unclear processes, or insufficient training can slow adoption and limit ROI. Effective change management ensures smoother transitions and faster value realization.

How eShipz Helps Optimize Shipping ROI

When a company like eShipz is used as the backbone for shipping operations, many of the above benefits can be realized, without requiring logistics leaders to build everything from scratch.

- Unified Platform & Carrier Intelligence: eShipz can provide a centralised platform that consolidates multiple carriers, allowing businesses to compare rates, choose the most cost-effective route, and reduce manual overhead. That leads to lower shipping costs, fewer manual errors, and better logistic efficiency.

- Real-Time Shipment Tracking & Visibility: Through integration with tracking systems and IoT/telemetry (as appropriate), eShipz can offer real-time visibility of shipments, helping supply-chain teams monitor status, anticipate delays, and plan proactively.

- Data-Driven Analytics & Reporting: With access to historical data, carrier performance metrics, shipment patterns, and cost analytics, supply-chain leaders can make informed decisions: optimizing route, selecting carriers, scheduling shipments, thereby maximizing shipping ROI.

- Operational Efficiency & Automation: By automating rate comparison, label generation, shipment scheduling and carrier allocation, eShipz reduces manual labour, administrative overhead, and human errors; especially in high-volume or complex operations.

- Risk Mitigation & Cargo Integrity: For clients shipping sensitive or high-value cargo, having reliable tracking, visibility, and data logging improves compliance, reduces risk of loss or damage, and ensures cargo safety, all contributing to improved ROI and reduced loss.

By leveraging these capabilities, companies don’t just get incremental improvements, they shift shipping from being a cost centre to a strategic advantage that supports growth, profitability, and competitive edge.

You can explore: https://www.eshipz.com/

In Closing

Shipping ROI is not a distant ideal, it is achievable today, with the right combination of technology, visibility, data, and execution. Smart shipping solutions transform logistics from a reactive chore into a proactive, data-driven, efficient operation. For supply-chain leaders aiming for long-term growth, reliability, and cost efficiency, investing in smarter shipping is no longer optional, it is essential.

If you are evaluating shipping strategies or looking to optimize your logistics, consider how a modern shipping platform could deliver real returns, not just in reduced cost, but in better visibility, faster transit, fewer risks, and scalable growth. Take the next step and see these capabilities in action: Book a demo with eShipz.