Studies show that retailers lose up to 10% of annual sales due to stockouts, while nearly 30% of customers switch brands when their preferred item isn’t available. A stockout happens when a business runs out of inventory and is unable to fulfill customer orders. This usually occurs due to unexpected demand, inaccurate forecasting, or supply chain delays. The stockout cost refers to the total financial and reputational loss caused by such situations, including missed sales, urgent restocking expenses, and the long-term impact on customer trust and brand reputation.

In India’s fast-moving ecommerce and retail environment, where customer expectations are higher than ever, even a single “out of stock” moment can have lasting consequences. Every missed order means a potential drop in revenue, a lost opportunity to delight a customer, and a hit to brand reliability. Understanding stockout costs helps businesses quantify these losses and take proactive steps to prevent them, ensuring both profitability and customer loyalty stay intact.

That’s exactly what we’ll explore in this blog. We’ll break down what stockout costs really mean, why they occur, and the types of expenses they involve. We’ll also look at how these costs can be calculated, their real impact on business operations, and practical strategies to minimise them. Let’s dive in and understand how managing stockout costs effectively can help your business stay ahead in a competitive market.

Understanding Stockout Costs

Stockout cost refers to the total financial and reputational expenses a business incurs when it runs out of a product and fails to meet customer demand. These costs include both direct and indirect losses.

Direct Stockout Costs

- Lost sales and profit: The most immediate impact is the loss of profit from the orders that couldn’t be fulfilled.

- Expediting costs: To recover quickly, companies often place urgent restock orders or pay extra for faster shipping.

- Lost productivity: Internal teams lose valuable time managing order cancellations, refunds, or rush replenishments.

Indirect Stockout Costs

- Lower customer satisfaction: Frequent stockouts frustrate customers, eroding trust.

- Damaged reputation: Repeated stockouts can hurt your brand image and reduce customer loyalty.

- Lost future sales: A disappointed customer might switch to competitors and never return.

- Increased administrative and backordering costs: Handling manual backorders and communication adds hidden costs.

In India’s competitive ecommerce ecosystem, where customers expect same-day or next-day delivery, even a short period of unavailability can cost a brand significantly.

The Impact of Stockout Costs on Your Business

A stockout might seem like a short-term problem, just a product temporarily unavailable. But in reality, its effects reach far beyond a single missed sale. From frustrated customers to disrupted operations, every stockout leaves a mark on both your revenue and your brand reputation.

- Customer Experience: One “out of stock” message is often enough to drive customers away. It can lead to abandoned carts, negative reviews, and a drop in repeat purchases, all of which directly affect customer lifetime value.

- Brand Trust: In India’s highly competitive ecommerce and retail space, consistent product availability signals reliability. When a brand frequently runs out of stock, customers begin to question its dependability, and rebuilding that trust can take years.

- Operational Inefficiency: Behind the scenes, stockouts cause workflow disruptions. Emergency restocking, higher logistics expenses, and unplanned overtime can drain both time and resources, reducing overall efficiency and productivity.

According to industry insights, over 75% of retailers experience frequent stockouts, causing substantial revenue losses averaging 3–10% annually, especially during festive or sale seasons when customer demand peaks and expectations are highest.

The true impact of a stockout goes beyond numbers; it affects how your brand is perceived and how your team performs. Recognising these ripple effects early helps businesses plan better, respond faster, and ensure that customers always find what they’re looking for.

How to Calculate Stockout Costs

Many businesses often ask, “What does a stockout really cost us?” or “How can we measure that impact?” While the exact value depends on your industry and product type, there’s a simple way to estimate it using a basic formula:

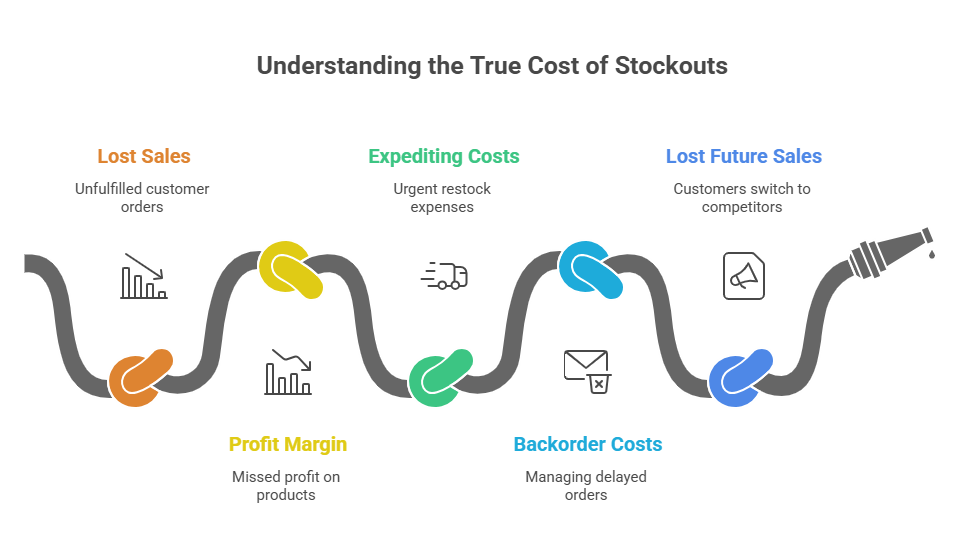

Stockout Cost = (Lost Sales × Profit Margin) + (Expediting Costs + Backorder Costs + Lost Future Sales)

Let’s break it down:

- Lost Sales: This represents the total value of orders you couldn’t fulfill because the product was out of stock.

- Profit Margin: The average profit you make on each product, this helps you understand how much profit was missed.

- Expediting & Backorder Costs: These are the extra expenses that come from placing urgent restock orders, paying for faster shipping, or manually managing backorders.

- Lost Future Sales: When customers face repeated stockouts, they might switch to competitors, and that potential lifetime value is also part of your loss.

Together, these factors give you a clearer picture of the true cost of every stockout, noot just the immediate sales you lose, but also the long-term effect on your brand and customer relationships.

Minimising and Preventing Stockout Costs: 5 Proven Strategies

Avoiding stockouts isn’t just about keeping shelves full, it’s about building a smarter, more responsive supply chain. For ecommerce and retail businesses in India, combining automation, visibility, and data-driven insights can make all the difference. Here are five practical ways to stay ahead:

1. Improve Demand Forecasting

Accurate forecasting is the foundation of stockout prevention. Use predictive analytics, past sales data, and seasonal trends to anticipate customer demand. This helps you order the right quantity at the right time, avoiding both shortages and overstocking.

2. Automate Inventory Tracking

Manual stock checks can’t keep up with fast-moving orders. Implement real-time inventory management tools that sync across all your sales channels. This ensures every team,from warehouse to customer service, knows what’s available instantly.

3. Build Supplier Redundancy

Relying on a single supplier is risky. Build relationships with multiple suppliers or local vendors so you always have backup options when demand spikes or delays occur. Supplier diversity adds flexibility and reduces downtime.

4. Set Safety Stock Levels

Always maintain a small buffer of high-demand products to cover unexpected surges or shipment delays. Calculating safety stock based on lead times and sales velocity helps you stay prepared without tying up excess capital.

5. Leverage Technology for Supply Chain Visibility

Technology plays a crucial role in preventing stockouts and ensuring smooth operations. Advanced inventory management tools, AI-powered analytics, and real-time dashboards help businesses forecast demand more accurately, automate reordering, and track stock levels across multiple locations.

By adopting these technologies, retailers can spot potential stock shortages early, make faster replenishment decisions, and maintain product availability even during peak seasons. When combined with the other strategies, this approach not only reduces stockout costs but also strengthens customer trust and operational efficiency, essential for long-term business growth.

Protecting Your Business from Stockouts

The most effective way to protect your business from stockout costs is by building end-to-end visibility and automation into your supply chain. When businesses have a clear, real-time view of their inventory and order flow, they can identify potential shortages before they turn into lost sales.

Take, for example, an apparel brand in India that sells across multiple online channels. By syncing all inventory into a single, unified dashboard, the brand gains a complete view of stock levels across warehouses and platforms. When quantities drop below a set threshold, automated alerts trigger timely reorders, preventing products from running out and keeping customers satisfied.

This kind of proactive inventory management doesn’t just reduce direct and indirect losses; it strengthens overall business resilience, ensuring your operations stay smooth even during peak demand seasons.

Conclusion

Stockouts may start with an empty shelf or unavailable SKU, but their true impact runs much deeper, affecting customer trust, sales performance, and overall supply chain efficiency. For growing ecommerce and retail brands, every delay or missed order can translate into lost opportunities and reduced customer confidence.

The key to avoiding this lies in visibility, accuracy, and automation. When businesses have real-time insight into inventory movement, smart replenishment alerts, and integrated shipping workflows, stockouts become preventable rather than unpredictable.

As modern commerce evolves, brands that invest in connected, data-driven operations don’t just avoid stockout costs, they build stronger supply chains, happier customers, and a competitive edge that lasts.

Analysing these moments helps companies strengthen their forecasting, collaboration, and visibility. Learn how eShipz helps turn this analysis into action