For many ecommerce and omnichannel brands, logistics now accounts for 10–15% of total sales, and in high-volume operations, it can climb even higher. These costs rarely spike overnight, they grow quietly through rising freight rates, delayed deliveries, return-to-origin (RTO) orders, and small operational inefficiencies that add up over time. Industry analysis from Freightos highlights how freight volatility and limited cost visibility continue to pressure logistics margins, while research from SuperProcure shows that data-driven logistics systems help brands gain better control over shipment-level costs and operational inefficiencies.

A useful benchmark for understanding these costs is the Logistics Cost Index (LCI), which measures the total cost of moving goods relative to economic output (like GDP) or tracks specific freight rates. Globally, the World Bank’s Logistics Performance Index (LPI) evaluates countries on customs, infrastructure, and efficiency. India’s LCI, calculated by NCAER for DPIIT, stood at 7.97% of GDP in 2024, improving from previous years, while India climbed to 38th place in the LPI in 2023, behind leaders like Singapore and Finland. These figures highlight the growing importance of investing in visibility, technology, and efficient logistics management to control costs and boost profitability.

In this blog, we’ll break down why logistics costs are becoming harder to manage, how technology is helping brands move from reactive firefighting to proactive planning, and where different industries are already seeing measurable improvements. As noted by

House of Shipping, sustainable cost reduction comes from process optimization and technology adoption, not short-term fixes. The goal here isn’t to chase the cheapest option, but to understand how smarter systems can create more sustainable profitability.

Why Logistics Expenses Are Increasing Across Supply Chains

Logistics costs today are influenced by far more than just distance or shipment weight. Brands operate across multiple sales channels, rely on several carrier partners, and face growing customer expectations around faster, more reliable deliveries. Each added layer of complexity introduces new cost pressures that are often difficult to track in real time.

Some of the most common drivers behind rising logistics expenses include:

- Fuel price volatility, which directly affects freight and line-haul rates

- Fragmented carrier networks, leading to inconsistent pricing and service quality

- High return-to-origin (RTO) and failed delivery rates, especially in ecommerce

- Manual processes, increasing errors, delays, and rework across operations

- Limited cost visibility at the shipment and order level

Industry research suggests that logistics expenses can account for 10–15% of total sales for ecommerce-led businesses, and often more for brands managing complex fulfillment networks..

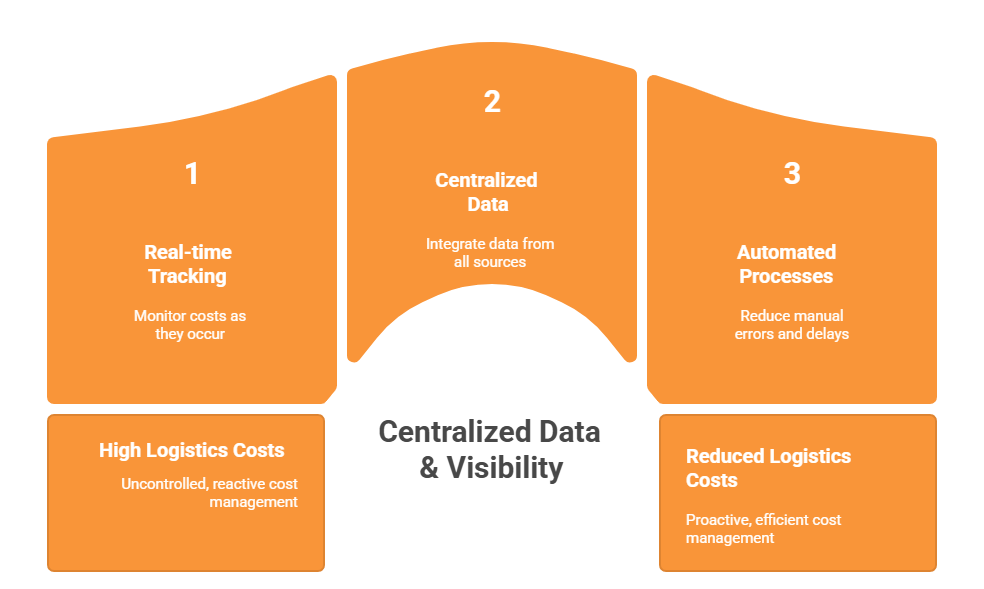

Without centralized data and real-time visibility, many teams only uncover cost overruns during monthly reconciliations, by which point corrective action is reactive, expensive, and often too late.

How Digital Logistics Systems Enable Better Cost Control

From reactive execution to proactive planning

Modern logistics technology is changing how brands manage costs. Instead of reacting to issues after orders are shipped, digital systems help teams plan ahead, bringing clarity to where money is being spent and why costs fluctuate across the supply chain.

When logistics data is connected across systems, teams gain the ability to make better trade-offs between speed, service, and cost. Rather than relying on manual checks or delayed reports, decisions are guided by real-time insights.

With connected logistics systems in place, brands can:

- Balance delivery speed with cost efficiency, choosing the right service level for each order

- Spot inefficiencies early, before small issues turn into large cost leakages

- Reduce manual intervention, lowering operational errors and dependency on firefighting

- Align logistics decisions with profitability goals, not just delivery timelines

More importantly, this shift isn’t about adopting one more tool. It’s about building a unified logistics intelligence layer, one that brings together fulfillment operations, transportation data, and customer experience into a single, actionable view. When teams operate with shared visibility, cost control becomes proactive rather than reactive.

Core Technology Capabilities That Drive Cost Efficiency

Not every technology investment leads to savings. The most meaningful cost reductions The most meaningful logistics cost reductions don’t come from cutting corners. They come from building capabilities that improve visibility, accuracy, and operational predictability across the supply chain. When brands can see what’s happening in real time and plan with confidence, costs stop slipping through the cracks.

Warehouse Automation and Robotics

Automation reduces dependency on manual labor, improves pick-pack accuracy, and shortens fulfillment cycles. Brands adopting warehouse automation often report lower per-order processing costs, faster dispatch timelines, and fewer fulfillment errors that lead to returns or re-shipments.

Predictive Analytics and Demand Planning

Advanced analytics help brands forecast demand more accurately and position inventory closer to customers. This reduces long-haul shipping, emergency stock transfers, and last-minute air freight, some of the most expensive logistics decisions teams make under pressure.

Transportation Management Systems (TMS)

A well-implemented TMS supports route optimization, load consolidation, carrier performance analysis, and freight cost comparison. Since transportation often accounts for the largest share of logistics spend, even small efficiency gains here can deliver significant cost savings at scale.

Real-Time Shipment Tracking and IoT Visibility

Live shipment tracking, such as the solutions offered by eShipz, allows teams to proactively manage delays, reduce losses from damage or theft, and intervene before issues escalate. This helps avoid downstream costs related to customer support, refunds, and replacement shipments.

Cloud-Based Integration Platforms

By connecting order systems, warehouses, carriers, and finance teams, cloud platforms eliminate data silos. This shared visibility enables faster decisions, cleaner reconciliations, and better alignment between operations and cost management.

Individually, each of these capabilities delivers value. Together, they create a logistics operation that is easier to control, easier to scale, and far less reactive. Instead of discovering cost overruns after the fact, brands gain the ability to prevent them in the first place. In an environment where margins are under constant pressure, this shift from guesswork to predictability is what turns logistics from a cost burden into a competitive advantage.

How Different Industries Are Saving on Logistics Costs

The benefits of logistics technology become most visible where volume, complexity, and customer expectations collide. While every industry faces rising logistics costs, the way those costs show up, and the way technology reduces them, varies significantly by business model. Below are examples of how different industries are seeing measurable improvements by modernizing their logistics operations.

| Industry | Challenges | Tech Solutions & Outcomes |

| Ecommerce & D2C | High orders, RTOs, last-mile issues | Smart courier allocation, tracking, NDR → fewer failures, lower delivery costs |

| Retail & Omnichannel | Spread inventory, inefficient transfers | Integrated inventory view → smoother replenishment, lower handling costs |

| Manufacturing & B2B | Bulk shipments, delivery delays | Predictive planning, freight consolidation → lower shipment costs, reliable delivery |

| 3PL & Logistics | Underused vehicles, SLA delays | Automation, analytics → better utilization, consistent service |

Across industries, the pattern is clear: logistics technology delivers the strongest returns where decision-making shifts from manual judgment to data-backed planning. As complexity increases, the ability to see, predict, and optimize logistics operations becomes a decisive factor in controlling costs and sustaining growth.

Trends and Data Influencing Logistics Spend Decisions

Logistics decision-making is no longer based on intuition alone. Brands that rely on data and technology-led frameworks are seeing measurable improvements in both cost predictability and service consistency. Industry research highlights that organizations adopting advanced logistics technology can anticipate cost fluctuations and proactively manage supply chain performance.

Key Trends Shaping Logistics Spend

- From Lowest-Cost to Best-Fit Carrier Selection

Instead of automatically choosing the cheapest shipping option, brands are selecting carriers based on route efficiency, delivery reliability, and service quality. This ensures better customer experience while controlling overall costs. - Increased Investment in Visibility and Analytics Platforms

Real-time tracking, predictive analytics, and integrated dashboards allow teams to spot inefficiencies early, optimize routing, and manage exceptions before costs escalate. - Focus on Cost-to-Serve Metrics

Moving beyond flat shipping rates, organizations are calculating the true cost of serving each customer or region. This helps identify high-cost areas, plan smarter deliveries, and balance service expectations against profitability.

These trends reflect a broader realization: logistics costs cannot be reduced sustainably without greater visibility, proactive planning, and smarter decision-making. Companies that invest in technology and data-driven processes are better positioned to optimize spend, improve service levels, and scale operations efficiently.

Profitability Is Now a Logistics Outcome

Logistics is no longer just an operational task, it’s a key lever for profitability. Brands that invest in visibility, automation, and data-driven logistics operations are better equipped to absorb market volatility, control costs at scale, and deliver consistent customer experiences.

What sets high-performing operations apart today is not just cheaper shipping, but smarter logistics intelligence. Platforms that unify shipping execution, real-time tracking, analytics, and carrier management into a single workflow make it easier to act early, correct faster, and scale efficiently. Tools like eShipz demonstrate how connected logistics systems help teams prevent costly surprises before they occur.

As logistics costs continue to rise across industries, the real differentiator will be how proactively brands manage them. The time to rethink logistics operations isn’t during a cost crisis, it’s before it begins.

Take the first step toward smarter logistics today and ensure your operations are ready for growth and cost control, don’t wait until inefficiencies eat into your margins.